Running a restaurant kitchen resembles conducting an orchestra where every musician plays a different instrument at breakneck speed. One moment your line cook burns the signature dish, the next your dishwasher calls out sick during Friday night rush—yet customers expect perfection every time. Proper kitchen management transforms this controlled chaos into seamless service that delights guests and keeps your staff engaged. This guide delivers actionable systems you can implement tomorrow to streamline operations, reduce waste, and maintain quality when the heat is on. You’ll discover exactly how to structure your kitchen for maximum efficiency without breaking the bank.

Implementing Your Kitchen Command Center

Your kitchen needs a central hub where critical information lives and decisions happen. Without this operational nerve center, communication breaks down and small issues escalate into service disasters. The command center prevents kitchen managers from constantly putting out fires by creating visibility into every aspect of operations.

Creating the Daily Management Dashboard

Transform a blank wall space near your expo station into your kitchen’s mission control with these elements:

- Shift checklist board tracking prep completion, equipment status, and staff assignments

- Inventory whiteboard showing par levels, low-stock alerts, and delivery schedules

- Quality control log documenting temperature checks, taste tests, and consistency notes

- Issue tracker where staff can anonymously report problems before they escalate

Pro tip: Use color-coded magnets—green for completed tasks, yellow for in-progress, red for urgent issues—so you can assess your kitchen’s health at a glance during service.

Establishing Pre-Service Command Meetings

The 15-minute meeting before doors open makes or breaks your service. Structure it with military precision:

- Review reservation book for special requests and large parties

- Confirm all stations have necessary ingredients and equipment

- Address yesterday’s quality control issues with specific solutions

- Assign backup positions for each staff member

- Set one daily excellence goal (e.g., “reduce ticket times by 2 minutes”)

This isn’t a pep talk—it’s a tactical briefing where every team member knows their mission. Document decisions in your command center logbook for accountability.

Streamlining Kitchen Workflow During Service

Peak service transforms even the best kitchen into organized chaos. Implement these systems to maintain quality when pressure hits maximum intensity.

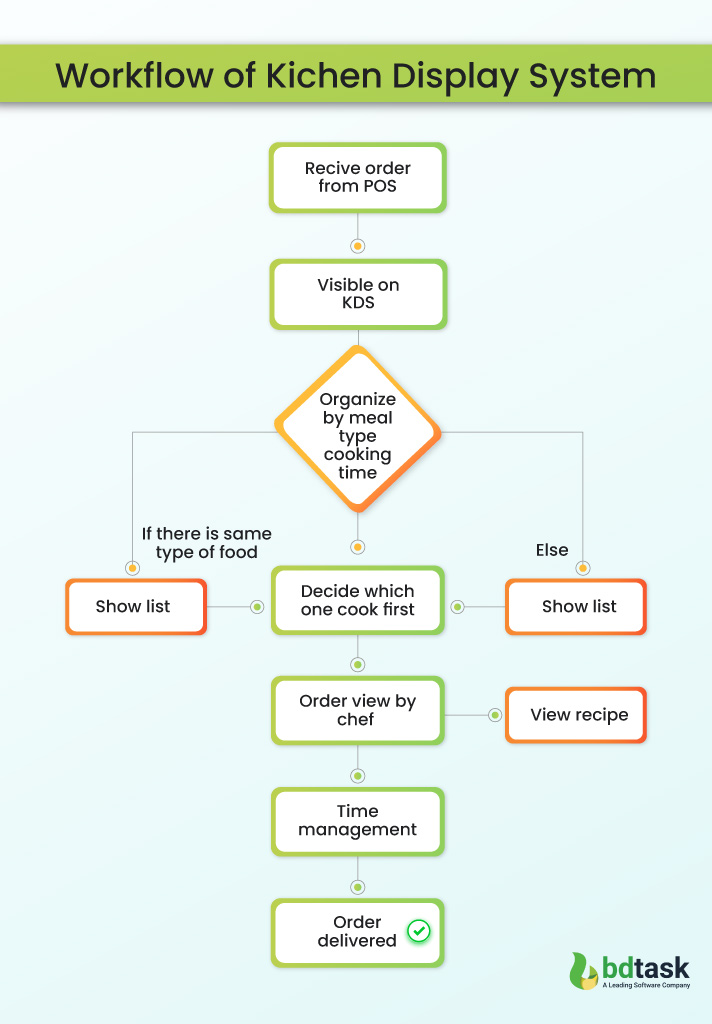

Perfecting the Ticket Management System

Most kitchen bottlenecks start with poor ticket handling. Standardize your approach:

- Staggered ticket release: Don’t flood the kitchen with all orders at once

- Visual queue system: Use ticket rails with color-coded clips (red for rush, blue for special requests)

- Time-stamped tickets: Automatically flag orders exceeding your target cook time

- Designated expo captain: One person solely responsible for ticket flow and plating consistency

When tickets pile up, your expo captain implements the “triage protocol”—identifying which items can be expedited without compromising quality.

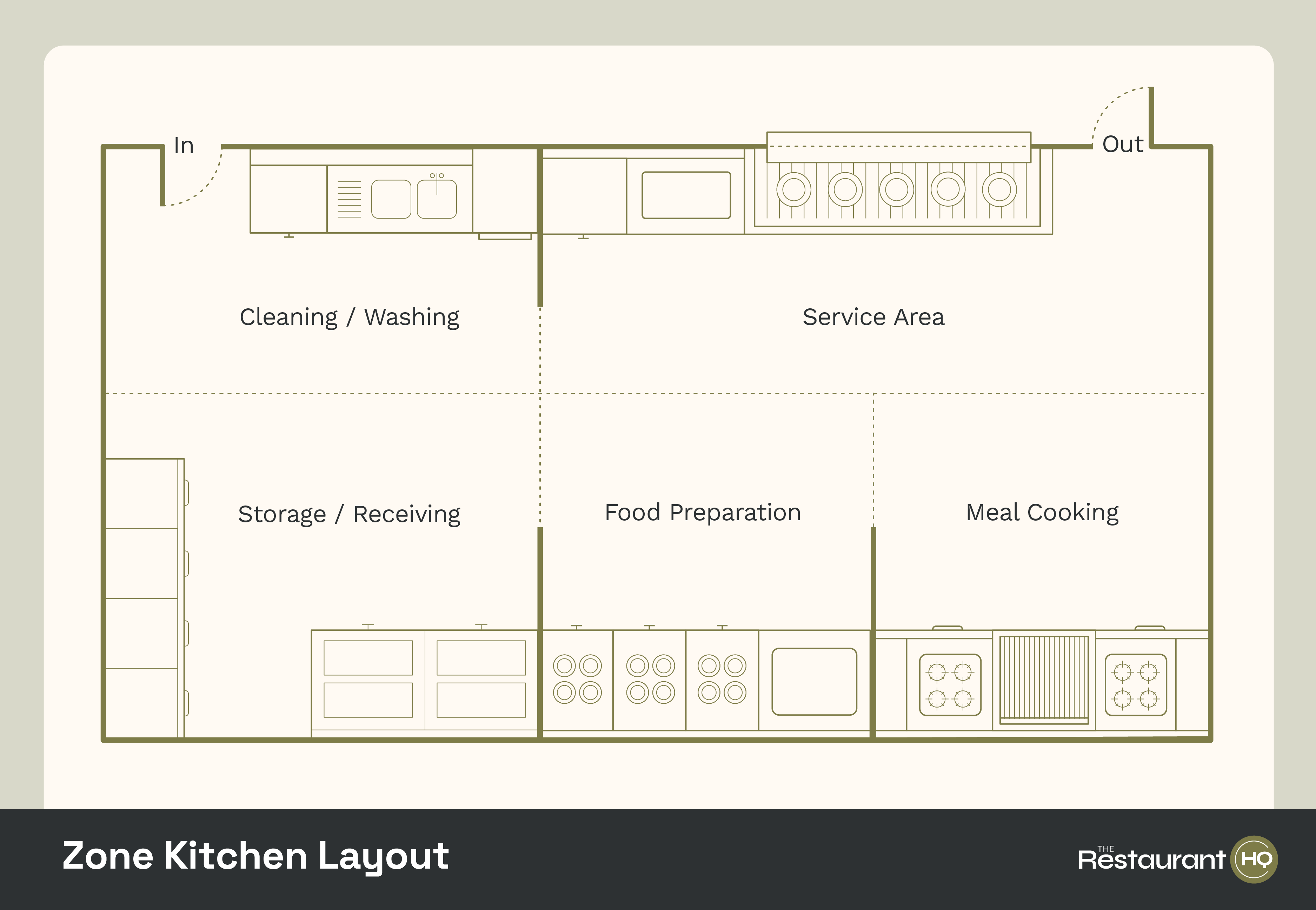

Managing Staff Movement Patterns

Kitchen collisions waste precious seconds during rush. Map and optimize staff movement:

| Zone | Purpose | Restricted Movement |

|---|---|---|

| Hot Line | Cooking | No non-essential personnel |

| Prep Area | Ingredient assembly | Only assigned prep cooks |

| Dish Station | Cleaning | Service staff only for drop-off |

| Cold Station | Salad/dessert assembly | No hot food carriers |

Conduct monthly “movement audits” using time-lapse video to identify traffic bottlenecks. Even saving two steps per order compounds into significant time savings.

Preventing Cost Leaks Through Inventory Control

Most restaurants lose 5-8% of revenue to preventable inventory issues. These systems protect your bottom line without sacrificing quality.

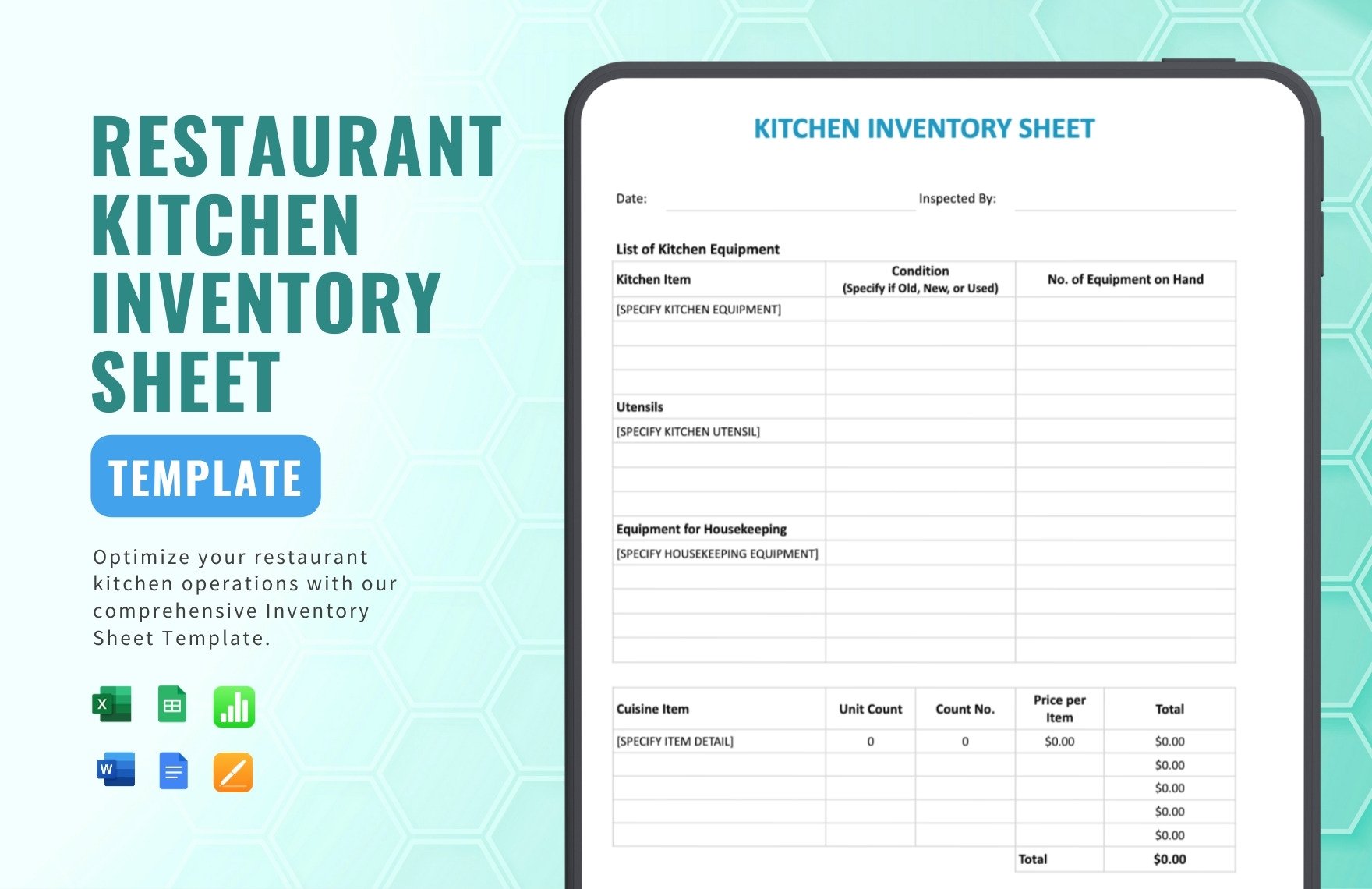

Conducting the Daily Inventory Snapshot

Forget monthly inventory counts—your kitchen needs daily visibility:

- Weigh all high-cost proteins at shift change

- Measure liquor and wine by volume, not bottles

- Track produce using standardized containers

- Document waste reasons with specific codes (SPOIL, OVER, ERROR)

Your kitchen manager reviews these snapshots each morning to adjust ordering before problems compound.

Standardizing Recipe Execution

Inconsistent recipes destroy profit margins. Lock in consistency with:

- Portion-controlled scoops and ladles for every sauce and component

- Digital timers for every cooking process (no “eyeballing” cook times)

- Pre-measured seasoning kits for complex dishes

- Recipe modification log tracking every deviation and its impact

When servers report a dish tastes “off,” you can immediately check if the recipe was followed precisely or if ingredient quality varied.

Building a Resilient Kitchen Team

Your staff turnover rate directly impacts food quality and service consistency. These retention-focused systems keep your best people engaged.

Creating Cross-Training Certification

Reduce single-point failures by ensuring every cook can cover multiple stations:

- Station mastery checklist with specific skills required

- Shadowing schedule where cooks rotate during slow periods

- Certification test with timed service simulation

- Cross-training bonus for certified multi-station cooks

A kitchen where every cook understands all stations operates with military precision during staff shortages.

Implementing Real-Time Feedback Systems

Traditional annual reviews come too late to fix service issues. Instead:

- Digital comment cards where servers instantly report kitchen issues

- Post-service huddles focusing only on improvement opportunities

- Peer recognition program where staff award points for exceptional teamwork

- Skill-building challenges with weekly goals (e.g., “perfect sear challenge”)

This continuous feedback loop builds accountability while recognizing excellence in the moment.

Maintaining Health Code Compliance Without Slowing Service

Health inspections shouldn’t cause panic. Integrate compliance into your daily rhythm.

Building Automatic Temperature Monitoring

Manual temperature logs get neglected during rush. Upgrade your system:

- Wireless probe sensors sending real-time alerts to manager phones

- Color-coded thermometers by food type (red for poultry, blue for seafood)

- Auto-logging systems that timestamp every reading

- Daily compliance dashboard showing all critical control points

When health inspectors arrive, you can instantly demonstrate your temperature history rather than fumbling through handwritten logs.

Creating Sanitation Stations That Get Used

Place sanitation tools where they’ll actually be used:

- Three-compartment sink with visual fill lines and timer

- Color-coded cutting boards matching ingredient storage containers

- Sanitizer test strips attached to spray bottles

- Handwashing sensors that log compliance rates

Make sanitation effortless by placing tools exactly where staff need them, not just where they fit in your layout.

Final Note: Sustaining Kitchen Excellence

Restaurant kitchen management succeeds when systems become second nature to your team. Start with your command center today—implement just one section of this guide tomorrow to avoid overwhelming your staff. Track your food cost percentage weekly; a well-managed kitchen typically operates 2-3% below industry averages. When unexpected challenges arise (and they will), your documented systems provide the playbook for consistent recovery. Remember that the best kitchens don’t avoid problems—they solve them faster than customers notice. For your next step, conduct a 30-minute workflow observation during Friday night service to identify your biggest bottleneck, then apply the relevant system from this guide to fix it before next weekend’s rush.