Ever wonder why your kitchen stays relatively smoke-free and odor-free even after frying fish or searing steaks? The answer lies in your kitchen chimney’s sophisticated engineering. Understanding how does a kitchen chimney work transforms it from a mysterious box above your stove into an essential ally for maintaining a clean, safe cooking environment. When cooking fumes threaten to coat your walls in grease or fill your home with lingering odors, your chimney springs into action—capturing contaminants before they spread. This guide reveals exactly what happens inside your range hood, helping you maximize its performance and troubleshoot issues when cooking smoke overwhelms your kitchen.

Kitchen chimneys operate through a precise combination of physics and filtration technology designed specifically for culinary environments. Unlike ordinary fans that simply move air, these specialized systems create an invisible barrier above your cooktop that intercepts rising smoke, steam, grease particles, and odors at their source. Whether your chimney vents outside or recirculates air back into the room, it employs multiple filtration stages to clean the air before release. By the time you notice lingering cooking smells, a properly functioning chimney should have already captured 80-90% of airborne contaminants—preventing them from settling on cabinets, walls, and countertops.

Why Your Kitchen Chimney Creates Powerful Suction

Your kitchen chimney’s ability to pull cooking fumes upward relies on carefully engineered airflow dynamics that overcome natural heat convection patterns. When you turn on the fan, it creates a low-pressure zone directly above your cooktop that actively draws contaminated air into the system before it can disperse throughout your kitchen.

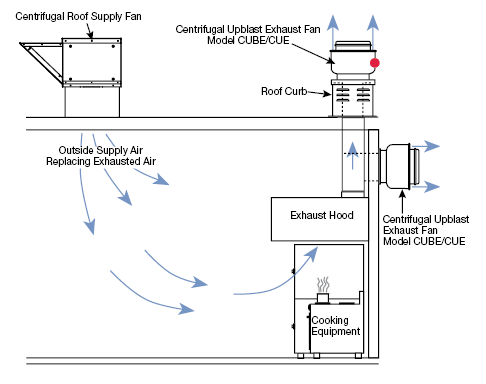

Centrifugal Fans Generate Maximum Pressure – Inside most high-performance chimneys, a centrifugal fan (also called a blower wheel) spins at high speeds to generate significant air pressure. Unlike ordinary axial fans that push air in a straight line, centrifugal fans use curved blades to fling air outward through the chimney housing using centrifugal force. This design creates higher static pressure—essential for pushing air through long duct runs or multiple filtration stages. When you hear your chimney humming steadily during cooking, that’s the centrifugal fan working at 200-1,000 cubic meters per hour of airflow capacity, depending on your model.

Optimal Placement Maximizes Capture Efficiency – For your chimney to work effectively, it must be installed at the correct height above your cooktop—typically 24-30 inches for electric ranges and 30-36 inches for gas ranges. This strategic positioning places the chimney within the “capture zone” where rising cooking fumes are most concentrated. The chimney’s canopy width should match or exceed your stove’s width to prevent fumes from escaping around the edges. When properly positioned, your chimney creates an invisible “air curtain” that intercepts cooking emissions before they can spread beyond your cooking area.

How Kitchen Chimney Filters Trap Grease and Odors

Kitchen chimneys employ multiple filtration stages to address different types of cooking contaminants. Understanding how these filters work helps you maintain optimal performance and choose appropriate replacement parts when needed.

Why Baffle Filters Outperform Other Grease Traps

Baffle filters—those curved metal components inside your chimney—use physics rather than just surface area to capture grease particles. As contaminated air passes through the series of curved baffles, it’s forced to change direction multiple times. This rapid directional change causes heavier grease particles to separate from the air stream and adhere to the filter surfaces through inertia. High-quality baffle filters capture 80-90% of airborne grease, significantly outperforming cheaper mesh alternatives. Their stainless steel construction withstands repeated dishwasher cycles, making them both effective and durable. When you notice your chimney struggling with greasy cooking emissions, check if your baffle filters are saturated—clean filters maintain optimal airflow while dirty ones restrict performance.

Carbon Filters Eliminate Cooking Odors in Recirculating Systems

While grease filters handle particulate matter, carbon filters tackle the gaseous compounds responsible for stubborn cooking odors. These filters contain activated charcoal—a specially treated form of carbon with microscopic pores that provide enormous surface area for adsorption. As air passes through the carbon filter, odor molecules chemically bond to the charcoal’s surface, effectively removing them from the air stream. In recirculating chimneys (those without external venting), carbon filters are essential for odor control since all air returns to your kitchen. However, these filters have limited capacity—they typically require replacement every 3-6 months depending on cooking frequency. When cooking smells persist despite regular filter cleaning, it’s time for a carbon filter replacement.

Ducted vs. Recirculating Systems: Which Works Better?

The fundamental difference between ducted and recirculating chimneys determines how completely they remove cooking contaminants from your kitchen environment.

Ducted Systems Provide Complete Air Removal – When your chimney vents to the outside through properly installed ductwork, it removes 100% of captured contaminants from your home. The duct system carries smoke, steam, grease, and odors directly outside, where they dissipate harmlessly. This configuration offers superior performance, especially for high-heat cooking methods like wok frying or searing meats. For optimal results, duct runs should be as short and straight as possible using rigid metal ducting—avoiding flexible accordion-style ducts that restrict airflow. A well-installed ducted system maintains cooler kitchen temperatures by removing excess heat along with other contaminants.

Recirculating Systems Filter and Return Air Indoors – In apartments or homes where external venting isn’t possible, recirculating chimneys clean the air through multiple filtration stages before returning it to your kitchen. These systems require both grease filters (to capture particulates) and carbon filters (to remove odors) since all air remains indoors. While convenient for installations where ductwork isn’t feasible, recirculating systems have limitations—they cannot remove heat from your kitchen, and carbon filters require regular replacement to maintain odor control. Performance degrades as filters become saturated, making consistent maintenance crucial for these systems.

Critical Installation Factors That Impact Performance

Your kitchen chimney’s effectiveness depends significantly on proper installation—many performance issues stem from incorrect setup rather than equipment failure.

Height and Positioning Affect Capture Rate – Install your chimney too high above the cooktop, and rising fumes will escape before being captured. Position it too low, and you’ll obstruct your view while cooking and risk fire hazards from proximity to flames. The ideal height creates a “sweet spot” where the chimney intercepts cooking emissions at their most concentrated point. Professional installers measure this precisely based on your cooktop type—gas ranges typically require slightly greater clearance than electric models due to taller flames and higher heat output.

Duct Configuration Determines Airflow Efficiency – For ducted systems, every bend and restriction in your venting path reduces effective airflow. A straight, short duct run using rigid metal piping maintains maximum extraction power, while long, convoluted paths with multiple bends can cut performance by 30% or more. The duct should terminate with a proper exterior vent cap that prevents backdrafts and pest entry. Sealing all joints with aluminum tape (not ordinary duct tape, which degrades in heat) ensures no contaminated air leaks into your walls or attic space.

Essential Maintenance Practices for Peak Performance

Kitchen chimneys require regular maintenance to sustain their original performance levels—neglect leads to reduced effectiveness and potential fire hazards.

Monthly Filter Cleaning Prevents Grease Buildup – Grease filters should be cleaned monthly in households with regular cooking. Baffle filters typically go in the dishwasher, while mesh filters may require manual scrubbing. Never operate your chimney without filters in place—this allows grease to accumulate inside the fan housing and ductwork, creating significant fire risks. When cleaning filters, check for warping or damage that might reduce their effectiveness even when clean.

Quarterly Deep Cleaning Maintains Airflow – Every 3-6 months, inspect and clean the chimney’s interior components. Grease can accumulate on fan blades and inside the housing even with regular filter changes, gradually restricting airflow. Use a degreaser specifically formulated for kitchen equipment and a soft brush to remove buildup without damaging surfaces. While performing this maintenance, check electrical connections and mounting hardware to ensure everything remains secure.

Troubleshooting Weak Chimney Performance

When your kitchen chimney struggles to control cooking emissions, systematic troubleshooting identifies the root cause without unnecessary service calls.

Check Filter Saturation First – A sudden drop in extraction power usually indicates saturated filters. Remove and inspect grease filters—even if they look clean, microscopic grease buildup can significantly restrict airflow. Clean or replace filters according to manufacturer recommendations, then retest performance. If extraction improves, establish a more frequent cleaning schedule based on your cooking habits.

Inspect Ductwork for Obstructions – For ducted systems, check the entire duct run for kinks, blockages, or disconnected sections. Outdoor vent caps sometimes get blocked by bird nests or debris, particularly after seasonal changes. Remove any obstructions and ensure all connections remain tight and properly sealed. Straightening convoluted duct paths can dramatically improve performance in systems that were marginally effective when newly installed.

Understanding how does a kitchen chimney work empowers you to optimize its performance for your specific cooking needs. From the centrifugal fan generating powerful suction to the multi-stage filtration system capturing grease and odors, each component plays a vital role in maintaining kitchen air quality. Whether your system vents outside or recirculates air indoors, proper installation, regular maintenance, and timely filter replacement ensure your chimney continues protecting your kitchen surfaces and air quality. By recognizing the signs of declining performance and addressing issues promptly, you’ll extend your chimney’s lifespan while keeping your cooking environment clean, safe, and pleasant for years to come.